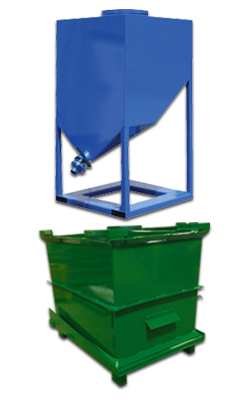

Foundry Material Handling Hoppers

We provide a wide range of self dumping material handling systems that can endure years of heavy use. Hoppers that are engineered with versatility an usability in mind.

Custom capacities and dimensions are manufactured with heavy steel construction, 3” fork opening, low center of gravity, and a compact footprint.

During the curing process, castings coming off of the production line fit perfectly into our wambox material hoppers. Once the box is full, a forktruck driver can easily lift the hopper and tranport it to

the secondary process where our clamshell hinge design allows easy removal of the contents by utilizing only a forktruck.

Made of heavy duty 7ga material with a double bottom construction that's filled

with used foundry sand to deafen the noise created while loading the material handling hopper. Our superior design gives you the ability to stack multiple hoppers vertically when not in use.

Material Handling Hoppers in a custom capacity to meet your requirements